Do you know why pressure vessels are designed into these strange shapes?

A pressure vessel is a sealed device that holds gas or liquid under pressure. It typically consists of a cylinder, a head, flanges, sealing elements, openings, nozzles, supports, and various other internal components. There are many ways to categorize pressure vessels. Based on their geometric shape, they are primarily classified into four types: cylindrical, spherical, rectangular, and combined.

Shape classification is a straightforward way to categorize pressure vessels. Today, Materials Doctor will discuss the differences and functions of pressure vessels of different shapes based on their shape.

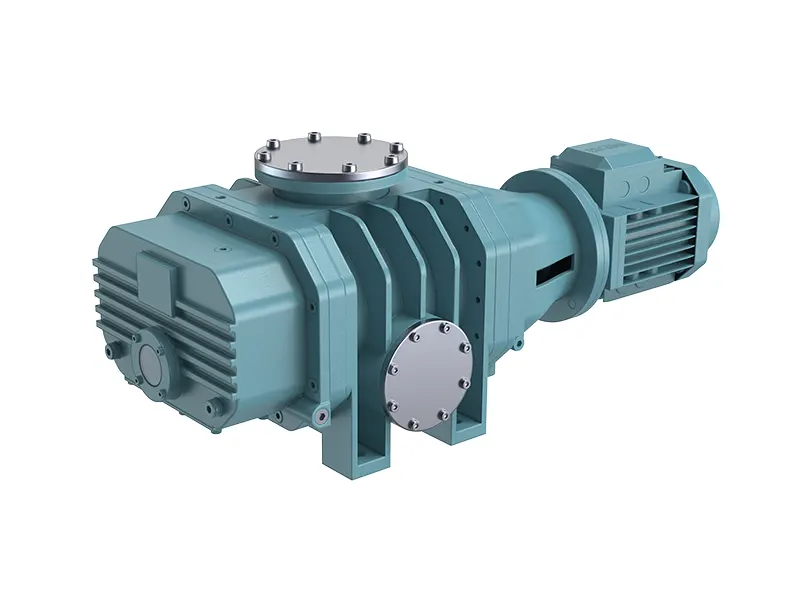

1. Cylindrical Pressure Vessels

The basic structure of a cylindrical pressure vessel consists of a cylinder, a head, nozzles, access ports, and supports. Its main advantages are ease of manufacture and the convenience of installing internal process components. Therefore, its production and usage are greater than those of spherical or rectangular vessels.

Cylindrical vessels are commonly used in petroleum and liquefied petroleum gas (LPG) storage tanks. Small LPG storage tanks are typically made in this cylindrical shape, while larger ones are constructed using different geometries. 2. Spherical Containers

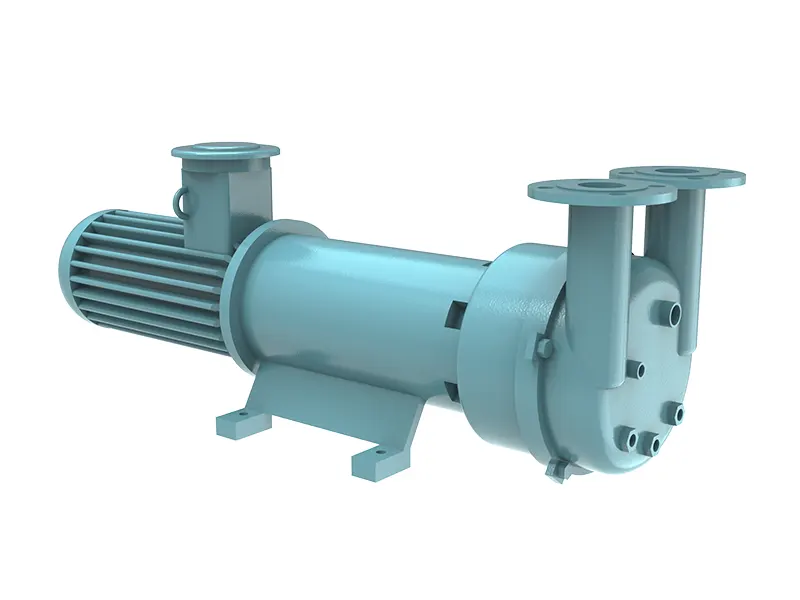

Spherical containers, also known as spherical tanks, have a spherical shell. They are an effective and economical pressure vessel for storing and transporting various gases, liquids, and liquefied gases.

Compared to cylindrical containers, their main advantages are: uniform force distribution; high load-bearing capacity for the same wall thickness; and smaller surface area for the same volume. Due to these factors, spherical containers generally use less steel than cylindrical containers. Their main disadvantage is the complexity of manufacturing and construction. They are widely used in the chemical, petroleum, refining, shipbuilding, and city gas industries.

3. Rectangular Containers

Rectangular containers, also known as square containers, generally carry gases or liquids at relatively low pressures. Currently, these container shapes are relatively rare because they are prone to deformation, which can lead to accidents. Furthermore, the cost of designing a rectangular container is higher than that of a circular container. Therefore, rectangular containers are relatively uncommon.

Eng

Eng  简体中文

简体中文  العربيّة

العربيّة